Criteria for Selecting a Sensortherm Pyrometer

Measuring Temperature

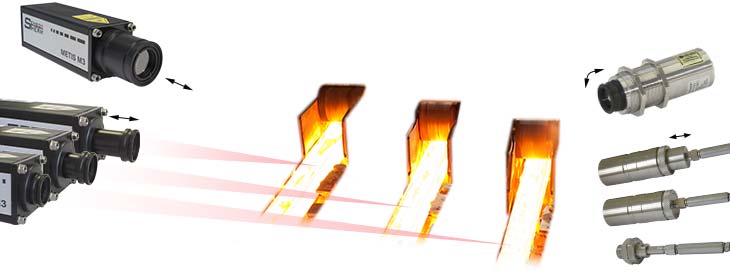

![]() The pyrometer measuring range is selected according to the required temperature of the object.

The pyrometer measuring range is selected according to the required temperature of the object.

Material / Spectral Range

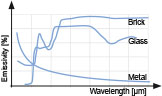

The material to be measured largely determines which spectral range of the pyrometer should be selected. For metal measurements, the shortest possible spectral range for a precise measurement is advantageous. Due to technical reasons the beginning of a temperature range may be limited to a higher starting temperature, therefore a model must be selected with a slightly higher spectral range, e.g. longer wavelength. To compensate for product temperature differences all devices are equipped with an adjustable emissivity setting. Other materials are usually measured in specially rated pyrometer wavelengths found by material analysis as suited for this purpose. The field of application is explained by the respective pyrometer models, but also we are pleased to advise you.

The material to be measured largely determines which spectral range of the pyrometer should be selected. For metal measurements, the shortest possible spectral range for a precise measurement is advantageous. Due to technical reasons the beginning of a temperature range may be limited to a higher starting temperature, therefore a model must be selected with a slightly higher spectral range, e.g. longer wavelength. To compensate for product temperature differences all devices are equipped with an adjustable emissivity setting. Other materials are usually measured in specially rated pyrometer wavelengths found by material analysis as suited for this purpose. The field of application is explained by the respective pyrometer models, but also we are pleased to advise you.

Pyrometer Type

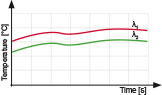

Most measuring object temperatures can be determined well with standard 1-channel pyrometers. However, in some cases the choice of a ratio pyrometer (2-channel pyrometer) is required, which simultaneously measures in two spectral ranges and determines the temperature by quotient formation. The common use of such devices is at measurements through polluted viewing glasses or at measuring objects that are smaller than the pyrometer‘s spot size. However, for an error-free measurement an increasingly polluting of the viewing window must run with the same absorption factor in the two spectral ranges, otherwise varying degrees of deviations will arise at different measuring temperatures.

Most measuring object temperatures can be determined well with standard 1-channel pyrometers. However, in some cases the choice of a ratio pyrometer (2-channel pyrometer) is required, which simultaneously measures in two spectral ranges and determines the temperature by quotient formation. The common use of such devices is at measurements through polluted viewing glasses or at measuring objects that are smaller than the pyrometer‘s spot size. However, for an error-free measurement an increasingly polluting of the viewing window must run with the same absorption factor in the two spectral ranges, otherwise varying degrees of deviations will arise at different measuring temperatures.

Response Time / Exposure Time

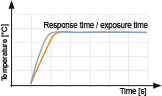

For all Sensortherm pyrometers the response time t90 is specified. It specifies the time after which 90% of the measured value is available to the pyrometer’s outputs. The shorter exposure time is only relevant when using a maximum value storage (peak picker), as this executes his calculations faster prior to signal output. The faster the response time of a pyrometer, the faster a measured value is output. This is particularly important when measuring parts move quickly, or when using a scanner, or if the pyrometer’s measuring value should be used to further system control.

For all Sensortherm pyrometers the response time t90 is specified. It specifies the time after which 90% of the measured value is available to the pyrometer’s outputs. The shorter exposure time is only relevant when using a maximum value storage (peak picker), as this executes his calculations faster prior to signal output. The faster the response time of a pyrometer, the faster a measured value is output. This is particularly important when measuring parts move quickly, or when using a scanner, or if the pyrometer’s measuring value should be used to further system control.

Outputs

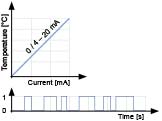

Depending on the application, different outputs are required. Almost all devices are equipped with a standard analog output 0/4-20 mA (selectable) and a digital interface RS232 or RS485. Via interface the pyrometer can be parameterized remotely, or a measurement data evaluation or the entire system can be controlled via PC program or a PLC. The data transmission with RS232 is only possible over relatively short distances, via RS485 very long transmission distances can be realized and multiple pyrometer be connected in a bus system to an interface. Some devices can also be supplied with an integrated PID controller or a Profibus interface.

Depending on the application, different outputs are required. Almost all devices are equipped with a standard analog output 0/4-20 mA (selectable) and a digital interface RS232 or RS485. Via interface the pyrometer can be parameterized remotely, or a measurement data evaluation or the entire system can be controlled via PC program or a PLC. The data transmission with RS232 is only possible over relatively short distances, via RS485 very long transmission distances can be realized and multiple pyrometer be connected in a bus system to an interface. Some devices can also be supplied with an integrated PID controller or a Profibus interface.

Ambient Temperature

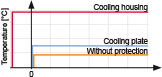

The device temperature must be within the specified limits in order to avoid inaccuracies or failures. At operations outside the ambient temperature the pyrometer must be installed in an appropriate protective housing (accessory).

The device temperature must be within the specified limits in order to avoid inaccuracies or failures. At operations outside the ambient temperature the pyrometer must be installed in an appropriate protective housing (accessory).

Optics

The pyrometer’s lens is selected according to the required spot size and measuring distance. At the focal point the spot size diameter is the smallest. Also de-focusing the optics will provide an average temperature of a larger spot. If the target under measurement is smaller than the spot size produced by the lens, the surrounding area is measured and averaged results in a lower or higher temperature (this issue can potentially be solved by choosing a 2-color / ratio pyrometer). The field of View (FOV) is the ratio of measuring distance to spot size and provides information about the quality of the lens. The larger the value, the smaller spot size can be achieved.

The lenses are in accordance with the measured infrared range of special glass, CaF2 or ZnS. For example at measurements through a window a glass material with similar transmission properties must be used at this place. 2-color pyrometers are equipped with specially calculated lenses to compensate the color aberration at the two measurement wavelengths.

Focusable Optics

With the focusable optics focus distances (smallest possible spot size at a certain distance) can be continuously adjusted within the minimum and maximum specified value.

Manually focusable optics measure pulled out at short measurement distances and inserted or pushed together with optical heads at long distances The shortest and longest measurement or focus distance is given in the data sheets, depending on the model ranges from 83 mm up to 10 m are possible.

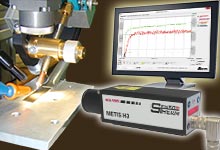

When selecting the motorized optics at Metis M3, the focus distance setting is made via the devices’ arrow keys or entered via software SensorTools when connected to PC.

Fixed Focus Optics

Fixed focus optics are fixed adjusted to a certain measurement or focus distance. Fixed focus optics in the Metis series are available with very small spot sizes with a distance ratio of up to 700:1, Metis M3 devices up to 900:1.

Sighting

The sighting is used to pinpoint the location of the measured target.

Laser targeting shows a red laser dot indicating the center of the measuring field. At the focus point of the lens the laser dot is the smallest and sharpest, so that the measuring distance for the smallest spot size can be determined easily.

The view finder provides upright imagery so that the target under measurement can be viewed visually. A circular reticle shows the measuring spot when the target is in focus.

Pyrometers with a color camera module provide a composite video output that can be connected to a TV or monitor. The pyrometer is focused and aligned via a target circle on the TV screen.